Tue Jan 05 2021

Supercritical carbon dioxide technology in ISO 6 Cleanroom for medical device development and sterilization processes

Guimarães, 05th of January 2021

Supercritical technology

The creation of supercritical fluid results from the combination of heating and pressure in such a way a chemical element will go beyond its critical point. The supercritical carbon dioxide (scCO2) is widely used in many industrial applications as a process or heat transfer fluid, as it combines liquid flow characteristics with viscosity and diffusion properties similar to a gas. Its critical point happens at low pressure and low temperature (73 bar and 31 degrees), making it an excellent candidate to produce more economic and technically feasible systems than those powered by other supercritical fluids. Another of its advantages is the fact that it can then be used as a replacement to polar solvents that are harmful chemicals. More and more supercritical CO2 is used in medical applications such as the impregnation of different value compounds or the deep cleaning of materials (elimination of hydrophobic residues such as trace oils, waxes, monomers, or lubricants).

Supercritical carbon dioxide (scCO2) technology in ISO 6 Clean Room

- Cleaning process Development

Supercritical CO2 can deeply penetrate porous solids. As such, it can generate a very effective cleaning in these types of materials. When used under mild conditions it causes no deterioration of treated materials’ mechanical properties. Furthermore, supercritical CO2 has bactericidal activity (thus ensuring a significant reduction in bioburden) and, as it becomes gaseous after depressurization, there is no need for a drying step. The fact that this technology effectively removes all solvent residues makes it particularly suitable for the removal of extractable or leachable compounds present in elastomers or cross-linked polymers, textile scouring, and degreasing porous materials.

Hydrumedical offers scCO2 deep cleaning under controlled conditions (ISO 6 cleanroom) in compliance with ISO standards.

After the deep cleaning, components are sealed and therefore can go for assembly processing, final sterilization, and packaging at customer facilities.

- Sterilization process Development

scCO2 sterilization is a fast, low-temperature alternative to Ethylene Oxide (EO) sterilization. A typical cycle for scCO2 sterilization can go from 30min to 8 hours (depending on the material) as opposed to Ethylene Oxide (EO) sterilization that requires cycles of a minimum of 14 hours. Plus, with scCO2 sterilization, there is no need for outgassing the chamber.

Using scCO2 for implants and medical device sterilization began with the idea that scCO2 has disinfection properties. Hydrumedical has optimized the technology using co-solvents solutions that increase the efficiency of the sterilization process. scCO2 sterilization achieves total inactivation of bacterial, viral, fungal, and yeast pathogens. When the effectiveness of our process is coupled with the benign nature of CO2, the results show an effective approach to sterilizing medical-grade products; many of which previously could not be sterilized using conventional means.

Hydrumedical offers an array of contract research services according to customer requests. These contract research services include the scCO2 Exposure Testing, Concept Viability Testing, and Sterilization Process Development. After the sterilization process, we perform sterility verification tests.

In 2019, the FDA announced two public innovation challenges to find alternatives to Ethylene Oxide sterilization. scCO2 sterilization was one of the chosen green technologies (see FDA Innovation challenge).

- Impregnation process

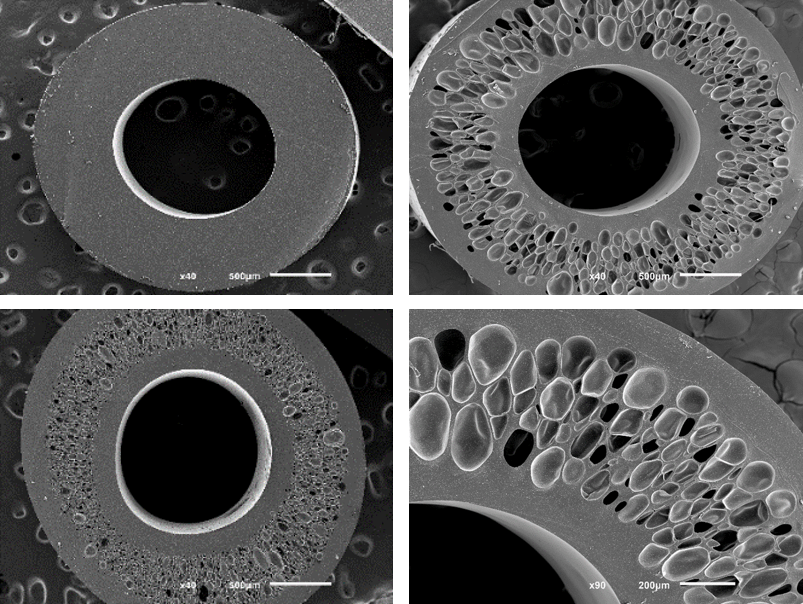

We have developed a patented technology that allows the functionalization of medical tubing. Our innovative patented method makes use of scCO2 technology and it enables a homogeneous and long-lasting impregnation of a wide range of compounds (lubricants, anti-bacterial agents, amongst others) into different substrates (silicone, polyurethane, and many others). This fast and economic process brings huge advantages over normal coating strategies as it penetrates the material without damaging it and allows the controlled released of the agent. This process will be carried out in controlled conditions (in house clean room (ISO6)) and according to medical devices regulation.

The method enables a homogeneous and long-lasting impregnation of a wide range of compounds.

About Hydrumedical (Hydrustent SA)

Hydrumedical’s main business has been, since its foundation in 2016, to support its customers and partners in the development of innovative and disruptive medical technologies, namely biodegradable ureteral stents (Hydrustent™), ostomy devices, and medical coatings for gastroenterology and urology. One of our key mission and the added-value proposition is to cross-feed the best practices applied to this challenging market, to foster added efficiency in the medical engineering processes applied to real-world projects, ultimately driving it to success.

Hydrumedical presents itself as a qualified and certified outsource R&D department, giving support in key points of medical device development: Intellectual Property strategy and management, engineering process development, testing, and validation as well regulatory support.

Contacts

address. Avepark (sala 213) – Parque Ciência e Tecnologia

Zona Industrial da Gandra

4815-017 Barco, Guimarães

mobile. +351 912 202 033

email. info@hydrumedical.pt

We use cookies to personalise content and ads, provide social media features, and analyse our traffic. To learn more check our cookies policy.